What Should be Considered when Selecting the Slime Dryer?

The price of coal has been soaring, which has also led to the rise in the price of slime. Recently, many customers have consulted about the investment of coal slime dryers. So what factors need to be considered when selecting a coal slime dryer?

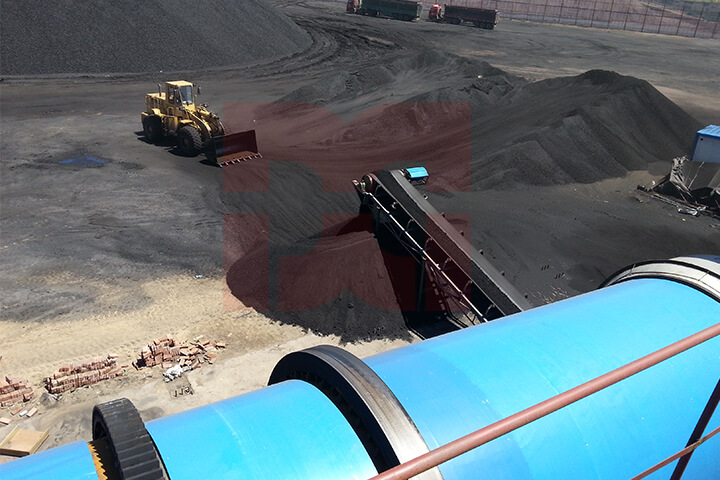

At present, the domestic coal slime drying method mainly adopts the internal dispersing rotary drum drying. The rotary dryer has many advantages such as continuous production, large processing capacity, low production cost, and easy control of product quality. When selecting the type, it is necessary to consider the moisture and cohesiveness of the raw coal slime, as well as the influence of low temperature environmental factors in winter. The low temperature in winter can meet the production needs of different seasons throughout the year, and an appropriate margin coefficient shall be reserved according to the regulations and specifications.

The layout of the drying plant is optimized according to the topography of the equipment installation site and the layout of other equipment and buildings. The drying equipment layout and specification selection are adjusted according to the reasonable suggestions put forward by the users. The drying equipment with simple process shall be selected as far as possible to reduce the subsequent maintenance cost of the equipment.